PET Bottled Water Filling Production Line

With Capacity 6,000BPH (600ML/1500ML PET bottle)

(PROPOSAL DETAILS)

1. Company Profile

Zhangjiagang luye Machinery Co.,Ltd is a modern technical enterprise set up to meet the 21st century's development demand regarding beverage packing machinery and all sorts of water treatment facilities. The co. has more than 30 years of production experience.It is a specialized enterprise producing full set of beverage packing machinery and all sorts of water treatment facilities integrating product development, scientific research & design, production manufacturing and technical service, marketing. At present, the co. provides following production lines:

Aerated beverage complete sets of production line.

Mineral water, Spring water complete sets of production line.

Pure water complete sets of production line.

Fruit juice complete sets of production line.

Bean milk & protein drink production line .

White spirit,soy,vinegar filling complete sets of production line.

Luye would like to move forward with you and will spare no efforts.

Main Product:

★ 3,000~36,000BPH carbonated beverage bottling line;

★ 3,000~36,000BPH purified water/ mineral water bottling line;

★ 3,000~36,000BPH tea/juice bottling line;

★ 3,000~36,000BPH milk/dairy bottling line;

★ 3,000~36,000BPH white/red alcohol drink bottling line;

★ 3,000~18,000cans/H cans beverage bottling line;

★ 100~2,000barrels/H, 3~5galon bottling line;

★ Blow moulding machine from 1000~24000BPH;

★ Water treatment system;

★ Beverage preparation system;

★ Turn key projects meantime.

Welcome to LUYE!

2. Quality Control

rotect the reverse osmosis device stable operating.

2-2-2、 Reverse osmosis device

It is setting a reverse osmosis machine whose throughput is 8m3/h.The pressure is having the effect on the water of going through the component and passing through the reverse osmosis, then going into the end treatment system after marshaling. Salt, machinery impurity and collide after deviating and condensing will drain into the outfall sewer with some water that going through the reverse osmosis.

The reverse osmosis unit should choose membrane of the high ratio of desalinization, good mechanical strength. Good chemical stability and big quantity of breaking through of water..

When RO is not work, it will auto-washing, press and arrange high TDS Water in the membrane and steel pipe and make the membrane into the water completely. It will stop the membrane from damaging for normal going through and after washing the pollution; it will get well maintenance of the set and RO membrane.

This unit is made up of one set washing medicine tank, one set steeled washing pump. One set 5μm filter, a set of meter and connecting pipe. When the membrane is polluting, it is used to chemical washing. The part of going through is resistance of acid and base.

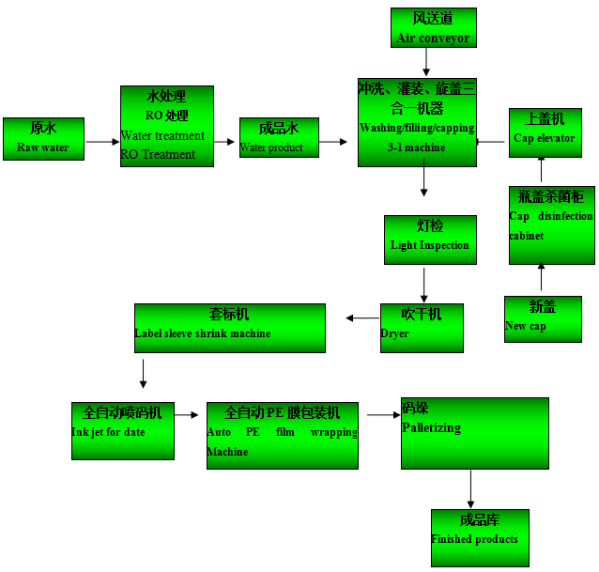

The process is as following:

cleaning tank──→cleaning pump──→cleaning filter──→reverse osmosis device

↑ ↓

└─────────────────────────┘

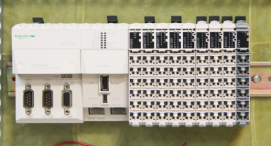

2-2-3、 Control part

The system adopts centralized control (automatically and manually) and process control imitation screen thus makes the running state clean and clear. All the water tanks are controlled with power pump.

(1) Raw water booster pump, dosing pump switch and index controlling; switch of high-pressure pump and low-voltage protection controlling

(2) Reverse osmosis device automatically clean with low pressure and large volume.

(3) Online display of reverse osmosis inflow water conductivity and effluent water conductivity

Part 2: PET bottle blow molding machine system

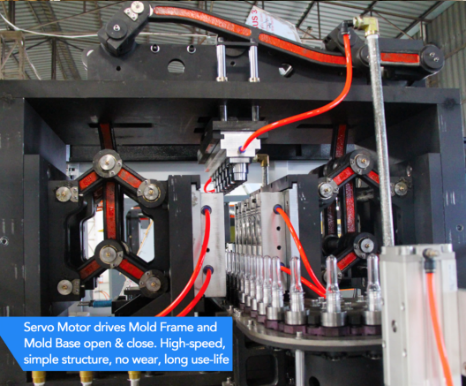

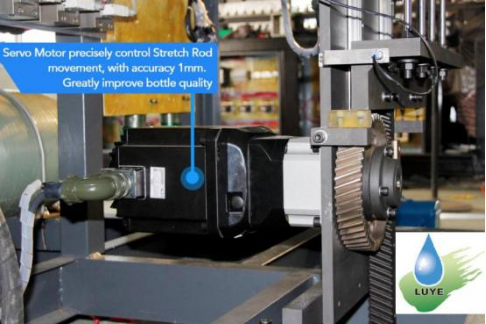

1.1Three Servo Motor Drive, makes machine drive system fully electrical.

a. Servo drives Preform Transfer System;

b. Servo drives Mold Clamping System;

c. Servo drives Stretch System.

1.2 XINJIE Motion Control System

Xinjie PLC Servo System as brain of the machine. PTO System (Pulse/Train/Output Servo Positioning Module) works on high speed positioning, with higher speed, higher noise immunity and precise positioning.

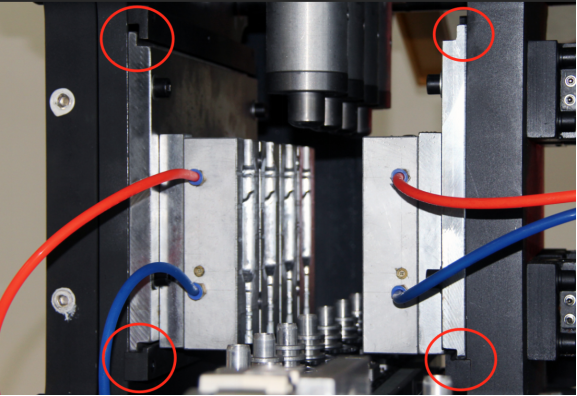

1.3 Mold Fixed by Drawer Design

Push the mold, fix the positioning screws. Mold changeover work can be easily done in half hour.

1.4 High efficient Infrared Lamp, Oven Constant Temperature Design.

a.The most advanced high frequency Infrared Lamp, increase heating efficiency 30%-50%.

b. Each layer of lamp are separately controlled, with assistant ruler on machine.

c. Intelligent temperature control system.

Temperature detector feedback to PLC automatically, PLC makes accurate judgment and then control circulation air in oven. It leads to constant temperature in Oven, free from voltage fluctuations and ambient temperature. It works when large ambient temperature difference (-28~45 ℃).

d. Preform self-rotation System, ensure every side of every preforms are heated evenly, which ensure quality of blown bottle.

e. Neck Cooling in Oven.

Preform Necks are cooled by recycling water, which avoid neck deformation.

Air conveyor system

Air conveyor profile

Air conveyor is a bridge between the PET bottle blowing machines and 3 in 1 filling machine. Air conveyor is supported by the arm on the ground; the air blower is settled on the air conveyor. Each inlet of air conveyor has an air filter to prevent dust coming into. Two set of photoelectric switch settled in the bottle inlet of the air conveyor, which can adjust the filling machine’s speed: “slow-down”, “stop”, “speed-up”, and “start”. The bottle is transferred to 3 in 1 machine through wind.

Main character

Except support arm etc. which are made of plastic or nylon material, other parts are made of SUS AISI304.

Air blower is settled with air filter to prevent dust coming into the bottle.

There is an adjustable joint settled in air conveyor. Do not have to adjust the height of unscrambler and air conveyor to meet the demand of different bottle, only adjust the height of bottle inlet.

There is a block bottle clear device driven by cylinder. When bottle block in the inlet, it clear the bottle automatic.

There is a photoelectric switch settled in the bottle inlet, when the bottle is detected, unscrambler stop. When the bottle leave the switch, unscrambler run again.

Main technical parameters:

1) Fan Model: F-9 type

2) Fan Power: 2.2KW/set

Part 3: PET bottled water filling, labeling, printing, packing system

1. XGF 18-18-6 water filling machine (3-in-1 type)

Main Features:

(1) The equipment is featured by compact construction, perfect controlled system, convenient operation, and high automatic level.

(2) It only need to change the star-style wheel of spiral cover and arch board to change different bottles,

(3) The spare parts connected with the material are made of stainless steel, non process dead angle, easily cleaned.

(4) It adopts high speed filling valve, accurate liquid level and non liquid damage, to ensure filling industrial art.

(5) Sealing cap is adopted magnetic force torque device, to ensure the sealing quality, and not to damage the cap.

(6) It adopts high efficiency arranging cap system, which is characteristic with complete self control and safety device.

(7) It’s equipped with perfect over-load protecting device, which can protect effectively the equipment and operator.

(8) The controlling system is featured by producing speed control, missing cap detect, auto stop when bottles are stuck, production accounted.

(9) Main electric and pneumatic component are imported world famous brand.

(10) The machine is adopted advanced touch screen control; human machine dialogue operation is workable.

XGF 32-32-10 as for you reference

2. Cap elevator and cap sterilizer

Introduction

There is a detector switch in the cap sorter, when the cap is not enough, when the detector on the cap sorter get a signal of lacking-cap, the cap elevator starts. The caps in the tank fall into the air by the function of the vibration motor and then pass though the air conveyor of the cap to the cap sorter. It can change the size of the tank inlet by the flashboard; this can adjust the speed of cap falling.

Technical parameters

(1) Model: SG- SG—Ⅱ

(2) Fan motor:380V,0.55KW

(3) Vibration motor:380V,60W

(4) Overall dimension: 1200×700×1290(L×W×H)

3. Bottle dryer

Introduction

Adopt high-pressure blower, discharge the air from a small gap, to blow off the water on the bottle body. The gap is laid incline, which can make the whole body touch the air. It consist of high-pressure blower, blowpipe, frame, control device, surge tank etc.

Technical Parameter

Dimension:500mm*500mm*800mm

Vortex Air Pump:5.5kw

4. Automatic Sleeve labeling machine

Equipment brief introduction

1. SPC-150D label sleeving machine:

In order to meet the needs of markets at home and abroad, our company has researched and developed double head mechanism to meet the requirements of casting label for bottle mouth and bottle body.

● Advantages: the machine can be used in two ways. It not only reduces a trapping label machine, but also saves the cost for customers

● It reduces the length of conveying line or avoids the secondary transportation, so that it increase the production efficiency and the floor areas of equipment;

● It reduces the stumbles in the process and increases the quality of product.

● Synchronized transmission,any change of transmission belt will be finished quickly.Compared to the type of traditional multilayer whose change and maintain need more than six hours,its maintenance is easy and maintain is simple ,so it doesn’t influence production.

● Unit cutter head plane design in China which apply to the container of ∮30mm—∮130mm.you never need to change or debug it.It also has unique light touch human-machine screen,that means,auto search original location as well as safety and convinence which is ahead of other congener products.

● Single shrinking label feed plane ,rensonal height which is convinent to fix the label;micro-computer auto figure which avoid enactment and adjustment .you only need to press it lightly ,the label will detect and locate automatially.The change of label is quick and convinent,besides,the cutt place is absolutely exact .

● Label feeding equipment:driving synchronized tensility control the supply of label ,the supply ability is 90meters per minite,volume label supply plane is ∮500mm,the internal diameter of paper tube will be 4’ ,8’,10’ .the configuration of label feeding is stable tensility which enable the exact length of label and the stable ,quick supply of label.

● The center pillar apply step by step shoot label structure and the speed is 150B-200B per minite.

● The newly designed cutter head use step by step motor driving which speed is high , action is exact,the cut is in order and the shrinking is beautiful.This design coorperate with the label synchronized location structure enable the precision of cut location within 1mm.

● Many emergency stop buttons enable emergency stop at the proper position along the production which gurantee the safe production.

● Special designed heat wind shringking tunnel use high pressure wing machine which makes the shrink effect perfect. Compare with the traditional shrink tunnel which cannot shrink curved bottle,this head wind shrink tunnel can make the shrink effect satisfying.

2. SPC-2000 Steam Shrinking Tunnel:

In the case of diffierent and irregular round bottles,square bottles and flat bottles etc, the new-style steam shrinking oven is easy to adjust and maintain.It has an even shrinking. The distribution of low-pressure steam drum and spouting way of steam are uniform and designed with seamless tube.The nozzle is divided to be adjustable three segments and the height ,position and steam output of every segment can be adjusted respectively so as to gain the perfect shrinking.The whole machine is made of stainless steel with heat preservation , which not only saves engery ,but also complies with the international safety standard .The stainless steel defrosting tray collects condense water.The whole machine adopts the water-proof design with the convenience of easy operation and low maintenance.

Based on the original confuguration, double layer holding furnace is manufactured to take effect on energy saving and environmental protection.The construction is 304 stainless steel and polished before delivery.

3. Characteristics of SPC-1200 Steam Generator:

The water is fed into the series of wholly automatic electrical heating generator by high pressure potential vortex pump made of copper with short water-supply time and durable service. A floating ball for liquid level is fixed in the water tank to automatically control the water inlet. Working system is all automatically controlled. After connecting the water supply and power supply for 5 minutes or so, it can output the steam continuously with high working efficiency.

5. Auto PE non-printed film shrink wrapping machine

1. Description

LYBS 6545 auto film wrapping machine is designed and manufactured based on the latest technology,for the demand of packing requirement of beverage production, as pure water,mineral water,juice,soft drink,etc. It is automatic wrapping, with shrink tunnel,packed perfectly.

2. Features of LYBS 6545 auto film wrapping machine

1) Automatic sorting conveyor system, which has the guiding separating stainless steel tube and the sorting plate making the bottles in standard roll for the wrapping purpose, to make sure that the group of bottles of 3 x 4, 4 x 6, or 2 x 6, 4 x 5 pcs of bottles in place for the wrapping need.

2) Automatic PE membrane processing part, which contains the upper and lower roll-feed PE membrane system in place and equipped with automatic infra-red sensoring system for checking the group of bottles being ready for wrapping and cutting sealing, the whole process is to be done instantly by the PLC control system.

The wrapped bottles will be pushed into the shrinking tunnel conveyor by the automatic pushing system, which pushes the wrapped bottle onto the conveyor of the shrinking tunnel.

3) Automatic hot wind shrinking tunnel, the shrinking system is the separated part of the machine has the separated controlling unit for the temperature controlled by touch screen temperature controlling system.

4) Touch screen control panel with PLC and electrical control system.

6. Conveyor System

Main features:

1. Stable conveying, using synchronous chasing control between the conveying belt and engine, making bottles in good condition in the conveying: non-falling, non-block, non-jam. And the cushion platform can be set before labeling machine, when the label is changed, the filling machine can keep working, no need to stop and waiting. The filled product during this period will be stored by the cushion, when label changing is finished, labeling machine will label the stored product in a high speed, and producing speed recovered.

2. Conveying belt is designed by module, component can be interchanged easily, structure is compact, noise is little, easy assembling and maintaining, have flexibility to combine the bottle type according to the different capacity.

3. The design of electrical control is advanced and rational, we can design the control method, select the electrical control component according to client’s layout, to improve the conveying stability.

4. Switch according to conveying system layout or customer reasonable requirement, for the convenience of operation.

5. Belt lubricating system is equipped

6. Main part all using SUS304.

7. Fringe board is using the U.S. Rexnord technology to produce.

Air conveyor for your reference

Bottle conveyor for your reference

3. Technical Service

Installation and commission

1、After the equipment arrived at the buyer’s workshop, the buyer should set it at a proper position according to the workshop layout. The seller will dispatch an experienced engineer for installation, commission and test production, which can meet the designed ability within planed time, installation and commission date is for 15 days. The seller should be responsible for providing related spare parts.

2、The buyer should tell the seller about the debugging time in advance. The seller will dispatch one engineer to the buyer’s factory for installation and commissioning and training, before the engineer arrival, all the conditions required for the whole line operation should be ready. The buyer should be responsible for the room and board and the go-back air tickets and visa fee, and the allowance of 300 USD per day for each person each day.

Training

1、The seller is responsible for providing technology training for the buyer; the items include equipment structure and maintenance. The train is undergoing at the buyer’s workshop, and the buyer will dispatch a qualified engineer to guide and set proper training scheme.

2、Through training, the engineer from the seller can grasp related operation and maintenance skills, adjust manufacturing technique skillfully and handle varies of obstacles on time.

Quality Assurance

1、Our company guarantees that all the equipment are new and have never been used. They adopt new design and made of proper material. They are also according to quality, specification and function of the contract in all terms.

2、We guarantee that all the equipment will reach their qualification after 5 days’ of correct installation and adjustment.

3、We guarantee that within the time of warranty, we will be responsible for any error, trouble and damage caused of the design, craftwork, manufacturing, installation, adjustment and material flaw.

4、Time of warranty for the whole machine is twelve months after check and accepts of the whole line.

In the time of warranty, if buyer find quality or specification of the machine is not accord with the contract or there is fault with the machine (includes potential fault and material flaw),buyer keep the right to ask for compensation from the seller with statutory machinery ‘ survey report

5、We assure you for the equipment’s mechanical function, product quality and product consumption target.

Maintenance period

1. We supply twelve month’s maintenance period after the check and accept of the machine. Seller supply the spare parts lost or damage cause by seller and supply effective service in time. When there is something wrong with the machine and after the feedback of the domestic customer, engineer should arrive at the factory within 24 hours and solve the problem.

2. After the maintenance time, we supply technical support and after sales service for life.

Equipment Acceptance

The seller provide equipment warranty and out-factory detecting report.

(1). Acceptance Standard

The quality index of the equipment complies with national or related industry standard.

1、Guarantee Capacity: 6000 bottles/hour ( based on 500ml)

2、The whole line efficiency: >85%

3、The passing rate of finished products: >99.8%

4、The sanitations index of the filling finished products complies with juice industry’s standard.

(2)Acceptance Procedures

After commissioned in the seller’s factory, and product inspect is acceptable, it will take pre-acceptance, if it’s acceptable, only after both sides sign signature can the equipment be sent.

1. After installed and commissioned in the buyer’s factory and inspect is acceptable, the engineer will show system function of the whole line. it’s will be final acceptance after gained buyer’s approval.

The training of operation and maintenance is undergoing at the same time, it will take effect after both sides sign signature.

Installation and commission time

1、Equipment process time: 60 working days;( on the premise of receiving the deposit, bottle and cap samples)

2、Installation and commission time: 15 days

Packaging and Transportation

1. Packaging Style

The packing carton is new, solid and exclusive packing one which fully complies with Chinese immunity standard, it’s suit for long distance transportation by sea and land and integral hoisting, moisture – resistant, ant-rust, anti-shock, anti rough handling in transit.

2. Shipping style: by sea

Post time: Nov-30-2022