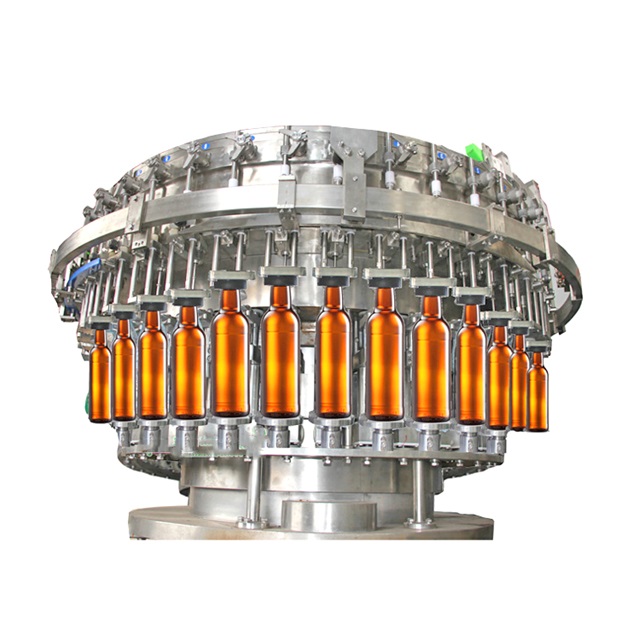

Beer Filling Machine Production Line

The filling machine has the function of closing filling valves when there is broken bottle, and washing away broken bottle. The vent pipe has automatic foam-removing device. The crafty cap-unscrambling and cap design with overloading protection and the function is sufficient. It is controlled by PLC.

ADVANTAGE:

A) PLC and Touch screen fully automatic control. Easy to operate.

B) Fastly replacement for different bottle size replacement.

C) Concise structure, reliable and durable, easy to maintain.

Main features

1) The rinsing machine use high-strength stainless steel bottles of spring-loaded folders, to ensure a stable reversal of the glass bottles.

2) Filling machine with spring-type mechanical lifting equipment to upload glass bottles, large bearing support floundering in the vat and use of guide-rod in the orientation of the structure, there are pre-cover features.

3) Use high-precision mechanical filling valve, with cylinder liquid level. The back pressure is controlled by a variable signal proportional. Fast, stable, accurate, vacuum one at a time.

4) Before capping, use hot water bubble set to displace bottlenecks’ air, ensuring the oxygen content of less than 0.15mg/l.

5) Filling machine includes broken bottle automatically stopping valve, broken bottle washing, and foam automatically exhausting device.

6) With perfect CIP cleaning function, and can also rinse the filling pipes with acid, lye liquid and hot water.

7) All the materials in contact with the valves, tanks, pipes are made of stainless steel 304 materials. Inside and outside the wall are mirror-polished to ensure healthy.

8) The whole operation adopts advanced man-machine interface, PLC control, frequency conversion stepless speed regulation and other automatic control technology. With no bottle no opening valves and no stamping, no cap no operation, and other security protection.